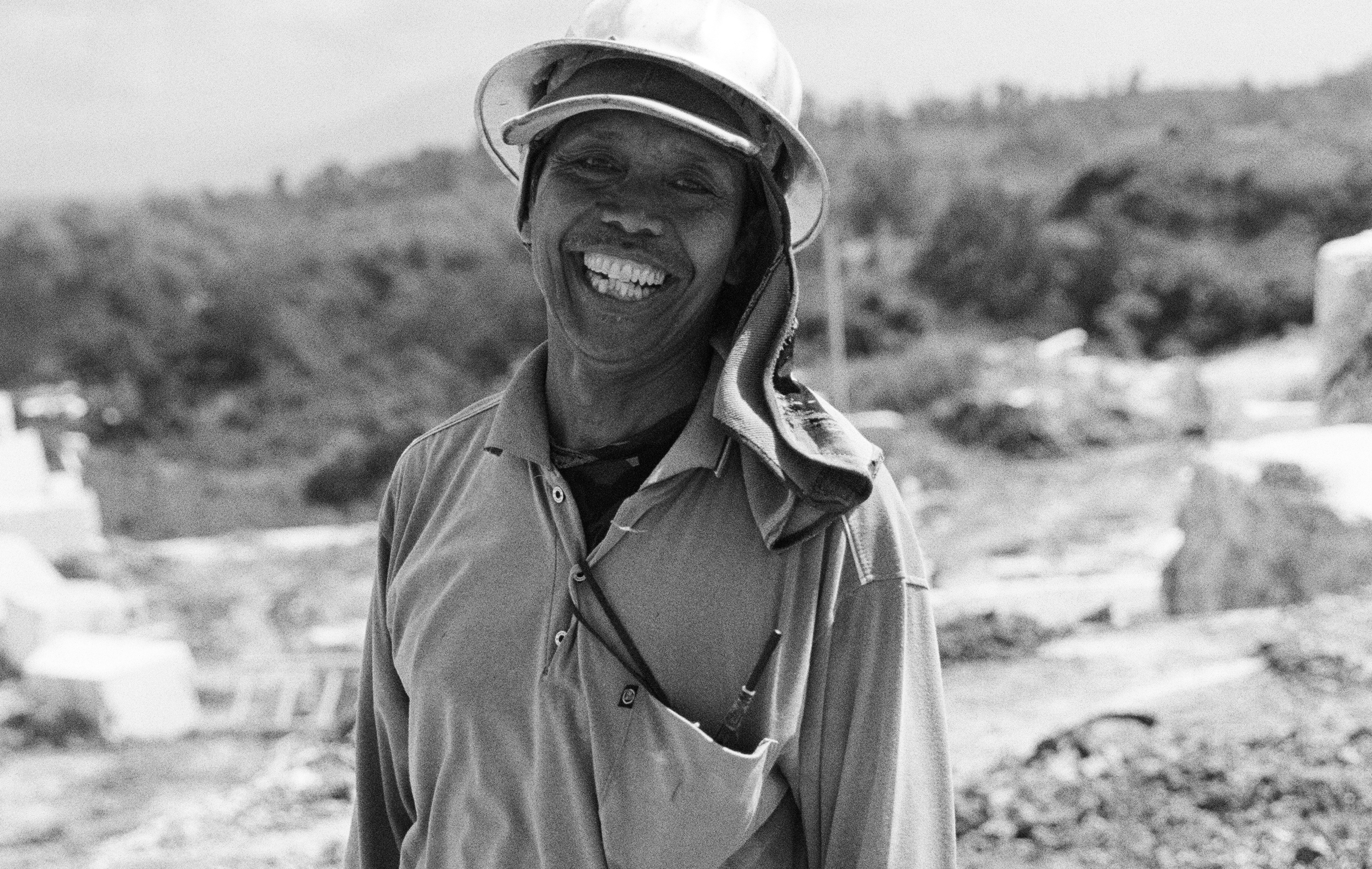

The Hands Behind

The hands behind

Hand crafted

All House of Slim pieces are hand-crafted by our talented artisans in a small local village in Central Indonesia, who have generations worth of knowledge and experience working with our signature elements. Each House of Slim statement piece can take anywhere between 15 - 70 hours to create, with intentional and slow craftsmanship embedded within our brand ethos.

Local Purchasing

We set out to create a line which worked in with artisans and localised natural elements in our home of Indonesia. Our Chapter I collection focusses on elements sourced and crafted from Central Indonesia by local villagers in their direct community. Many have grown up around the elements, with their parents paving the way and passing on their expertise.

Community Support and Education

Our factory supports its local community in many forms. All additional stones are donated to local villagers, free of charge – with many of the recipients breaking these larger pieces on site and supplying in smaller portions to local crafters, or local calcium producers. One significant story to us is an individual who has been breaking these stones for the last 40 years, successfully providing his children with the funds to undertake Masters degrees. The factory also provides financial assistance for staff and their family members for further education, as well as assisting in building credit profiles and better financing terms directly from the banks for their staff members. House of Slim chose to work with our community-minded factory due to their inclusive programs in expanding opportunities for a more prospering future.

Local and Equal Employment

Our partner factory staff members are all from the local area. Their management continue to provide training locally and if necessary training is also provided in the bigger cities. They encourage staff to visit trade shows locally and internationally so that they can understand trends in the industry technologies, as well as enabling the up-skilling process. Our factory also engages with the local training colleges, and provides dedicated students opportunities to learn and practise under the supervision of a skilled team.

Motion and 35mm film captured by Holly Chippindale